Ultrasonic welding systems for easy integration

The demand of the production industry for complex and efficient automation systems is constantly increasing. Herrmann offers a wide range of solutions for ultrasonic system integration. The basis is therefore sound ultrasonic expert knowledge and a modern product portfolio: From system integration and smooth start-up to production assistance and professional operator training - Herrmann Uprovides the general prerequisites for safe process-related implementation of a flexible automation system.

Advantages of Herrmann Ultraschall welding systems

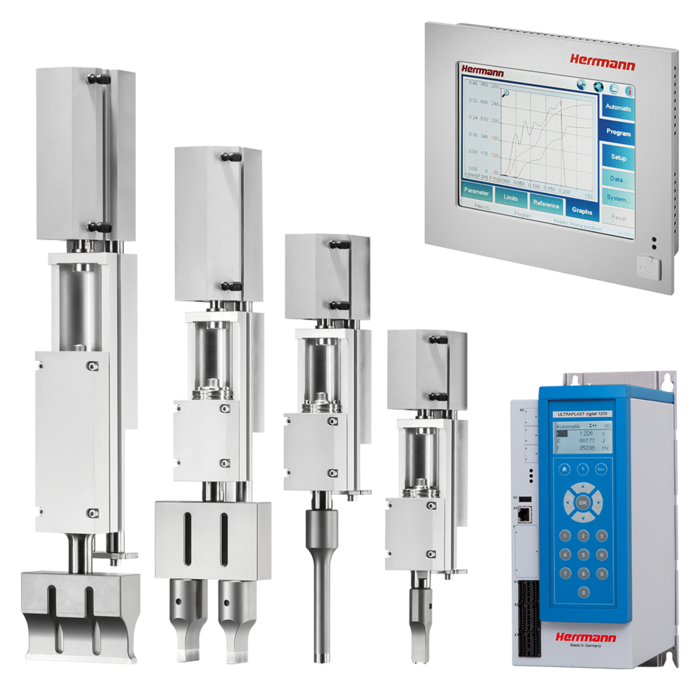

All weld systems in the HiQ modular, MPW product line and weld systems such as the actuators VE SLIMLINE or VE COMPACTLINE are characterized by:

- Proven technology from the series machine field for automation

- Weld process controllers allow optimal weld results

- Individually configurable to suit requirements

- Robust and reliable in continuous operation

- All-round application development consulting – APPLICATION ENGINEERING

Possible applications for ultrasonic welding systems

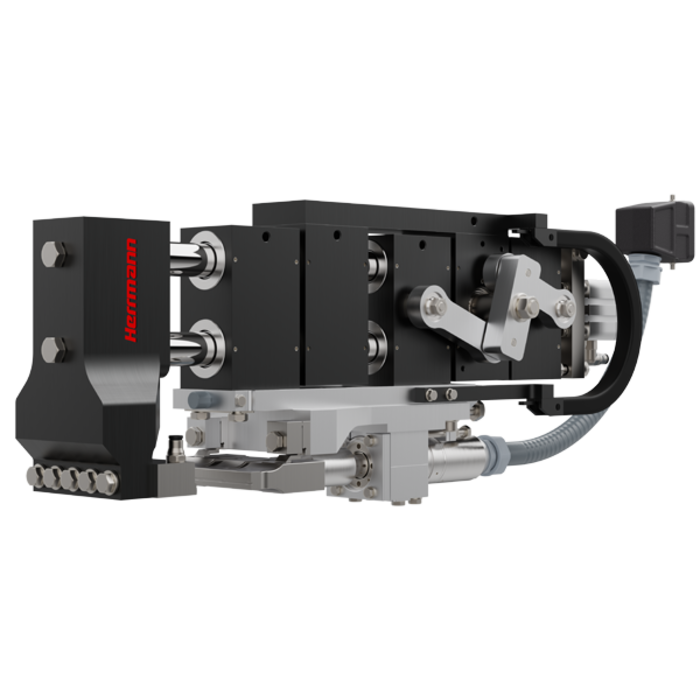

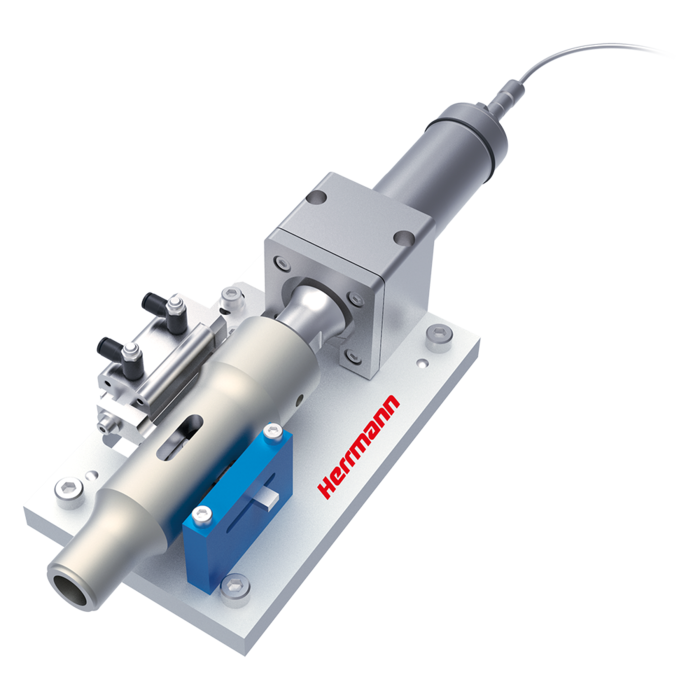

Herrmann provides standard actuators, HiQ, and HiS modules that offer a high level of flexibility that can be easily adapted to individual customer requirements. The modular system offers extensive integration solutions for machine builders and the automation industry. Be it for automation systems or for robot solutions: Each ultrasonic welding system forms a functional unit, allowing ease of integration and start-up. The ultrasonic welding systems are successfully used in the plastics and LI battery industries.

Individual ultrasonic welding systems

For the FOOD, HYGIENE, MEDICAL, BATTERY, CONSUMER industries, Herrmann provides further application-specific ultrasonic welding systems and modules. Further product descriptions under packaging technology and continuous ultrasonics.