Breaking through with ultrasonic welding machines of the HiQ series

Benefit from the know-how gained from thousands of solved applications and experience the trendsetting HiQ machine generation! Adapted to the needs of our customers, it delivers perfect welding results with unprecedented flexibility. From Automotive to Medical to Consumer: With machines of the HiQ series, you will find the right solution for your project and your budget – and always with quality "Made in Germany"!

Enjoy the benefits of the HiQ machine generation for a faster, safer and more economical welding process than ever before:

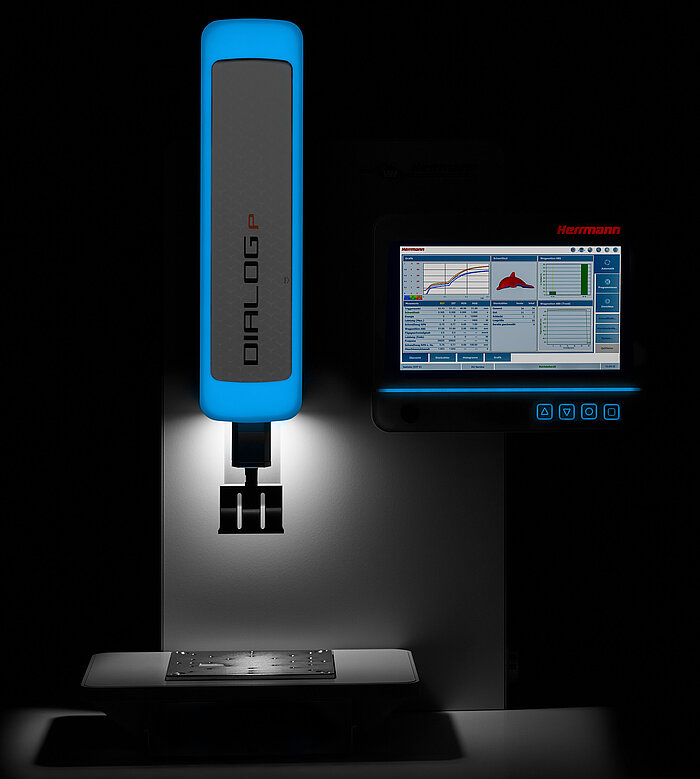

The HiQ P – for highest precision

For gentle welding of sensitive components or materials, it is necessary to use the lowest possible welding forces. The HiQ P is ideally suited for this, as it reliably provides reproducible, strong and precise welding results even at reduced forces.

- Lowest forces

- Reproducible welding results

- Compact, space-saving design

Our intelligent software provides you with an intuitive and user-friendly system for the operation of your HiQ machine.

The precise process control options and graphical visualization of parameters make a decisive contribution to reducing your waste and increasing the efficiency of your manufacturing.

| Machine type | HiQ DIALOG P | HiQ VARIO P |

|---|---|---|

| Frequency [kHz] | 35 | 35 |

| Control | DIALOG | VARIO |

| Generator power [W] | 1200 | 1200 |

| Outside dimensions [mm] | 1140x879x640 | 1140x879x640 |

| Drive | SpeedControl | PropControl |

| Weld force min./max.* [N] | 10-650 | 10-650 |

| Max. Stroke [mm] | 100 | 100 |

| Throat depth to center of sonotrode [mm] | 180 | 180 |

| Electrical height adjustment [mm] | 200 | 200 |

The HiQ S – pure flexibility

Thanks to the large workspace, the HiQ S is the ideal welding solution for both small and large-volume components. A high level of configurability and flexible control ensure an excellent user experience.

- Wide range of variants

- Reliable welding result

- Flexible use in production

Our intelligent software provides you with an intuitive and user-friendly system for the operation of your HiQ machine.

The precise process control options and graphical visualization of parameters make a decisive contribution to reducing your waste and increasing the efficiency of your manufacturing.

| Machine type | HiQ DIALOG S | HiQ VARIO S |

|---|---|---|

| Frequency [kHz] | 20 | 20 |

| Control | DIALOG | VARIO |

| Generator power [W] | 2400 / 4800 / 6200 | 2400 / 4800 / 6200 |

| Outside dimensions [mm] | 1483x982x760 | 1483x982x760 |

| Drive | SpeedControl | PropControl |

| Weld force min./max.* [N] | 30-2490 | 30-2490 |

| Stroke [mm] | 150 | 150 |

| Throat depth to center of sonotrode [mm] | 260 | 260 |

| Electrical height adjustment [mm] | 400 | 400 |

More than just design

Experience the welding workplace of the future today with machines from the HiQ series:

- The control system communicates with you using a customizable user interface.

- An intuitive arrangement of the controls ensures quick access to all important functions.

- Illuminated elements provide clear visual machine status information.

Awarded the IF Design Award 2021 and the Good Design Award 2020: the design of the HiQ offers a new dimension of communication and ergonomics – for perfect and reproducible joining results.

Guided tool change

Safe, fast, supported: While tool changing used to be a time-consuming task and involved a number of risks, with the HiQ generation of machines it is done in the shortest possible time.

The proven QCS (Quick Change System) has been further developed and thus ensures an even faster and safer change than usual.

Customizable. User-friendly. Digital.

Individually customizable to your needs: The HiQ is the first ultrasonics welding machine for series production with the highest flexibility in integrating peripheral devices. For you, this means maximum usability.

The behavior of all intelligent machine components and networked devices are digitally represented in the HiQ. This allows you to commission the machine faster and easier than ever before.

A smart bench top

With the HiQ machine generation, you get more than a welding machine that performs its basic tasks - you get an intelligent support for the safe and correct execution of your work.

For this purpose, a wide variety of sensors and tools can be connected to the HiQ, which will help the machine to warn you of errors in the production process or even prevent them in the first place.

"With the HiQ, Herrmann has developed a user-friendly and process-reliable welding solution. The simple approach to creating a new welding program has completely convinced me. Tool changes are also quick and uncomplicated on the HiQ machine generation."

Norbert Ennemoser, process owner at Ultra Reflex GmbH

Put to the test: the HiQ under customer review

Partner with Us

Contact our team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing. We look forward to hearing from you!