to 12 s per cycle is all it takes to weld smaller busbars.

of tensile force and more – benefit from strong connections.

thick busbars can be welded thanks to powerful components.

7 Benefits for Optimized Busbar Manufacturing with Ultrasonic Welding

Take advantage of new possibilities and developments in ultrasonic welding to join your busbars even faster, more reliably and more efficiently – thanks to a process that achieves extremely low contact resistance and maximum strength in copper-aluminum connections!

In our free white paper, you'll learn:

- How ultrasonics reliably welds even thicker busbars

- How you can optimize your cycle rates and output

- Technical advantages compared to laser welding, crimping and soldering

Discover the way to top-efficiency in busbar welding and secure your competitive advantage!

Unlock 60+ years of our know-how today

Successfully solved busbar applications

Video: Busbar Welding with Ultrasonics

Faster, safer, stronger: Discover innovative ultrasonic welding for your busbar application in our video. Together with you, we can develop the perfect welding solution for your individual requirements in one of our ultrasonic laboratories worldwide.

We're looking forward to your message!

Let's work together on your perfect solution

FAQ – Ultrasonic Welding for Busbar Production

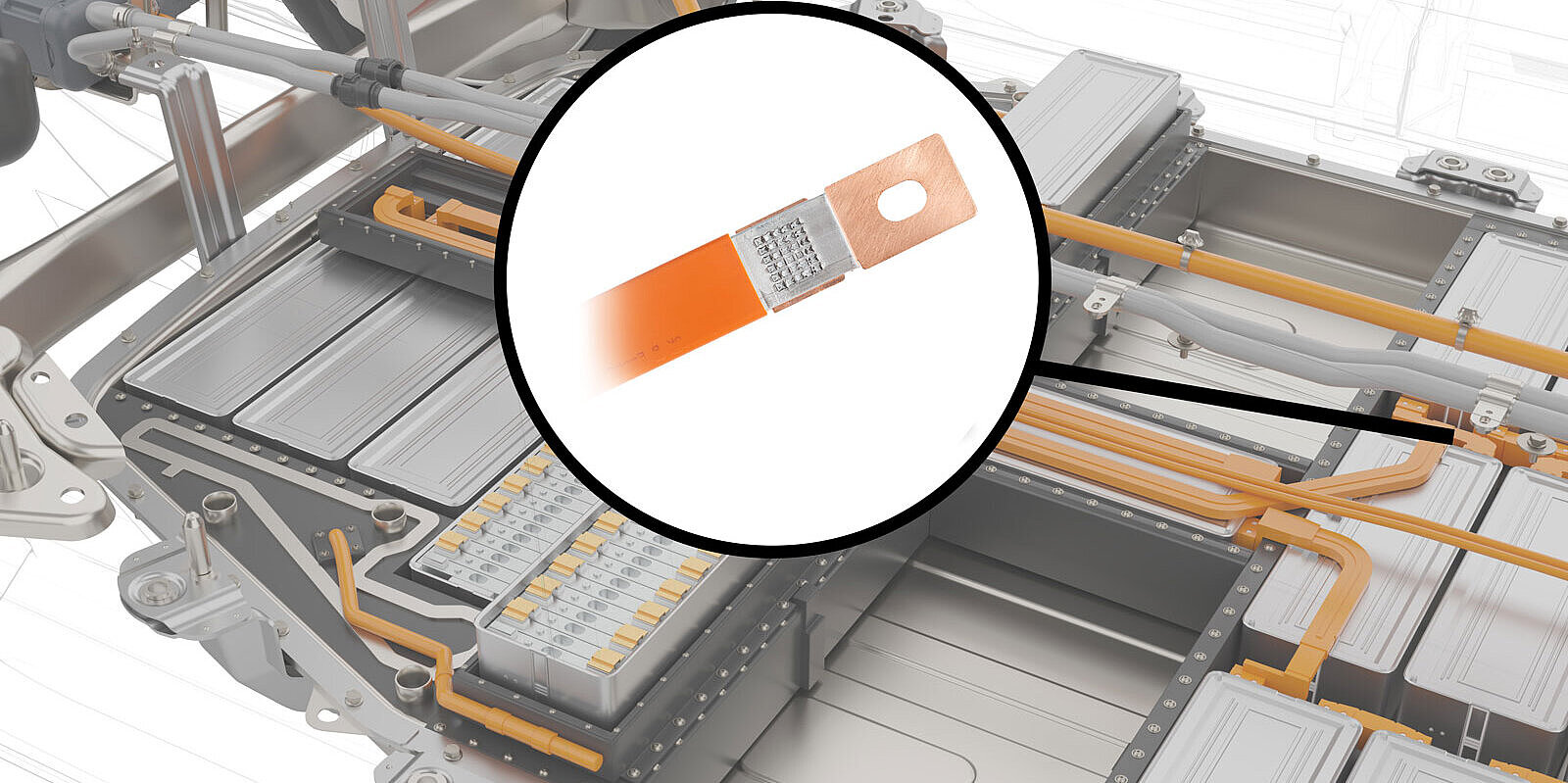

Busbars are a proven solution for electric vehicles (EVs) due to their ability to manage high-voltage and high-current loads within compact and lightweight designs. Compared to traditional wire harnesses, busbars offer up to 15 % higher power transfer thanks to their lower electrical resistance and optimized conductor geometry.

Their rigid, preformed structure simplifies assembly and enables highly automated installation processes, making them an ideal solution for series production with consistent quality. Busbars eliminate the need for manual routing, bending, or bundling as required with flexible cables. This not only saves time and reduces error risk, but also supports modular system design and faster line integration.

In tight EV architectures, busbars also offer advantages in packaging, thermal management, and electromagnetic compatibility (EMC). Multi-layer busbar configurations allow power and signal separation, improved shielding, and efficient space utilization—especially in battery packs, inverters, and distribution units.

Combined with reliable joining technologies like ultrasonic welding, busbar systems deliver long-term mechanical durability and extremely low contact resistance, even under vibration and thermal cycling.

Learn more about the benefits of ultrasonic welding for busbar manufacturing.

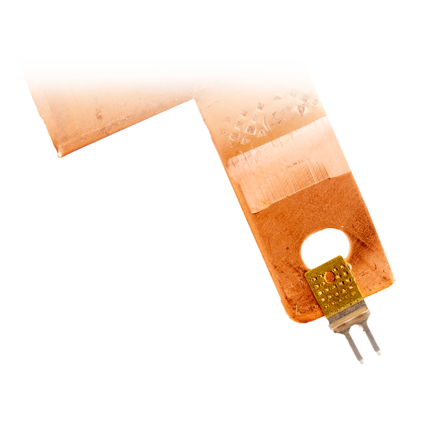

Ultrasonic welding ensures extremely strong and reliable connections — even for demanding applications in electromobility, power electronics or energy distribution. The connection is created by high-frequency mechanical friction under pressure without melting the material. The result: a tight connection with excellent electrical contact.

Compared to other joining methods like laser welding or soldering, ultrasonics is particularly convincing due to its high mechanical strength: Busbars welded with ultrasonics can withstand enormous forces — both in the shear and peel direction. Depending on the application, tensile forces of 5,000 N to 10,000 N and more are possible. The connection remains stable even during temperature cycles and vibrations, making it ideal for safety-critical applications.

Another advantage: the structured surface of the welding tools ensures that oxide layers of the metal parts are effectively fractured at the contact point. This results in an extremely low contact resistance, which ensures long-term electrical conductivity — even with mixed connections such as copper-aluminum.

For engineers and process owners, this means reliable, durable connections that meet the highest requirements in industrial production — without any additives and minimum thermal stress on the material.

Learn more about the benefits of ultrasonic welding for busbars in our free white paper.

Yes, ultrasonics are perfectly suited to permanently join different non-ferrous metals together. Unlike thermal processes, where different melting points and material properties often lead to problems, ultrasonics can be used to join mixed metals such as copper-aluminum or brass-aluminum firmly and reliably.

The welding process is purely mechanical – without melting, without solder. This effectively breaks up oxide layers, creating a highly conductive, corrosion-resistant joint. This is a decisive advantage, especially in electromobility and power electronics.

Ultrasonic welding is therefore the ideal solution for busbar applications that need to be connected with different non-ferrous metals.

Learn more about the benefits of ultrasonic welding for busbars in our free white paper.

Modern ultrasonic welding machines are ideal as ergonomic manual workstations or as integrated systems in automated production lines. The patented architecture of the ultrasonic components enables welding with minimum cooling times, so that even thicker busbars of up to 6 mm can be welded in the shortest possible time.

Thanks to short welding times and the precise control of welding parameters, the process is perfectly suited for automated production. Each individual weld is closely monitored — up to 150 pieces of data are available per process. This data can be used for further process optimization and quality control.

Individual welding machines used in manual processes are designed to be user-friendly and can be loaded quickly thanks to large engagement areas. This enables cycle times of 7 to 12 seconds for smaller busbar applications.

Learn more about the benefits of ultrasonic welding for busbars in our free white paper.

Thanks to our modular product portfolio, we have the right solution for every need.

Our ULTRASAFE X is a manual work station with a special focus on safe, intuitive, and ergonomic working. Individual auxiliary functions and modules can be added as required.

Our HiS VARIO X is our versatile system for integration into automated production lines. We are happy to assist you as your trusted advisor for all questions relating to integration.

Download More Expert Resources

Learn more about the benefits of our ultrasonic welding technology for your busbar application. Our downloads contain knowledge from more than 60 years of ultrasonics, providing valuable insights into advanced assembly techniques. By sharing our technical expertise, we foster a close partnership on equal terms, ensuring we can execute projects as quickly and successfully as possible.

Download our exclusive resources to unlock decades of innovation and stay ahead of the rapidly evolving electronics industry.

Partner with us to increase your efficiency and speed

Contact our team to discover how our premium solutions can increase the output of your busbar production. We look forward to hearing from you!