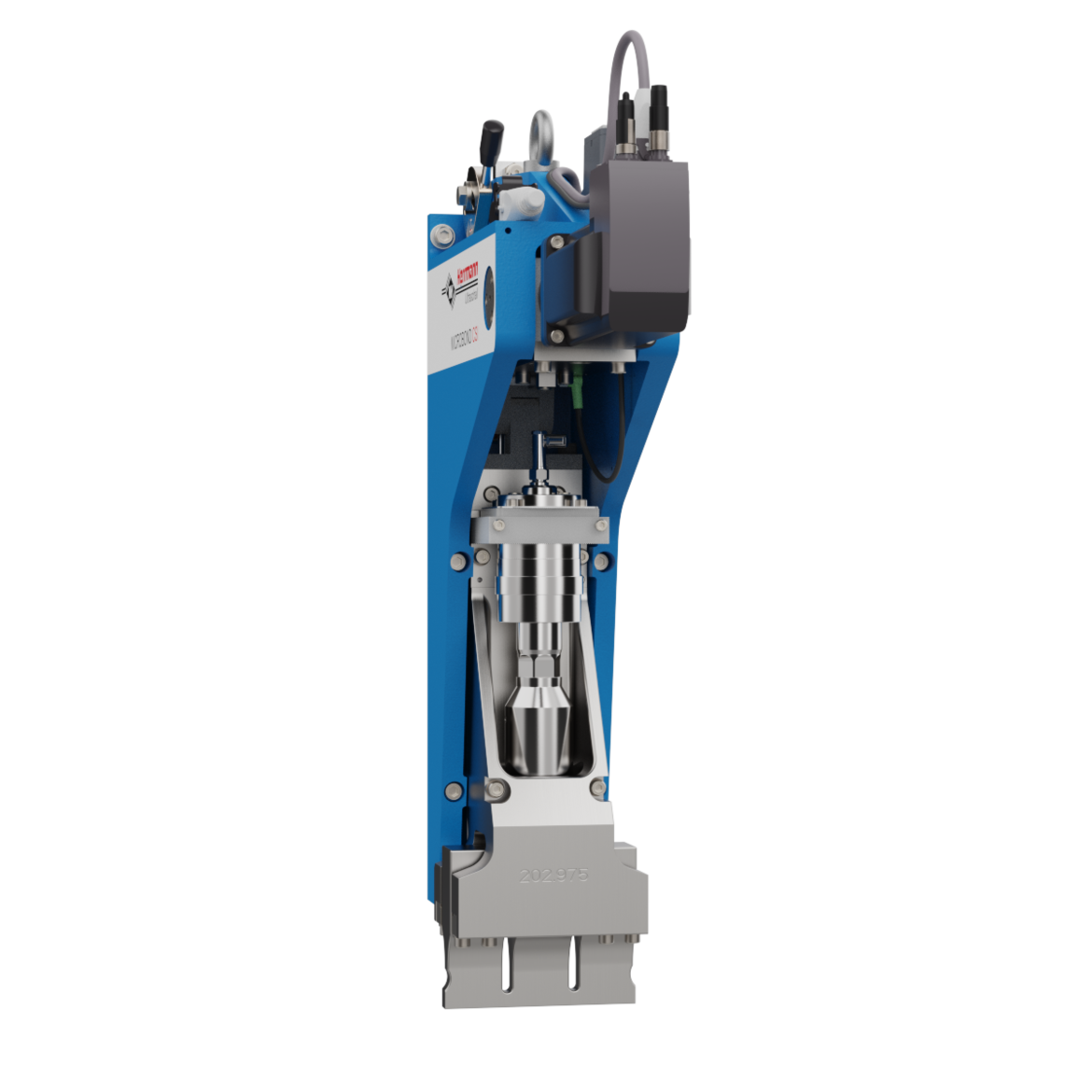

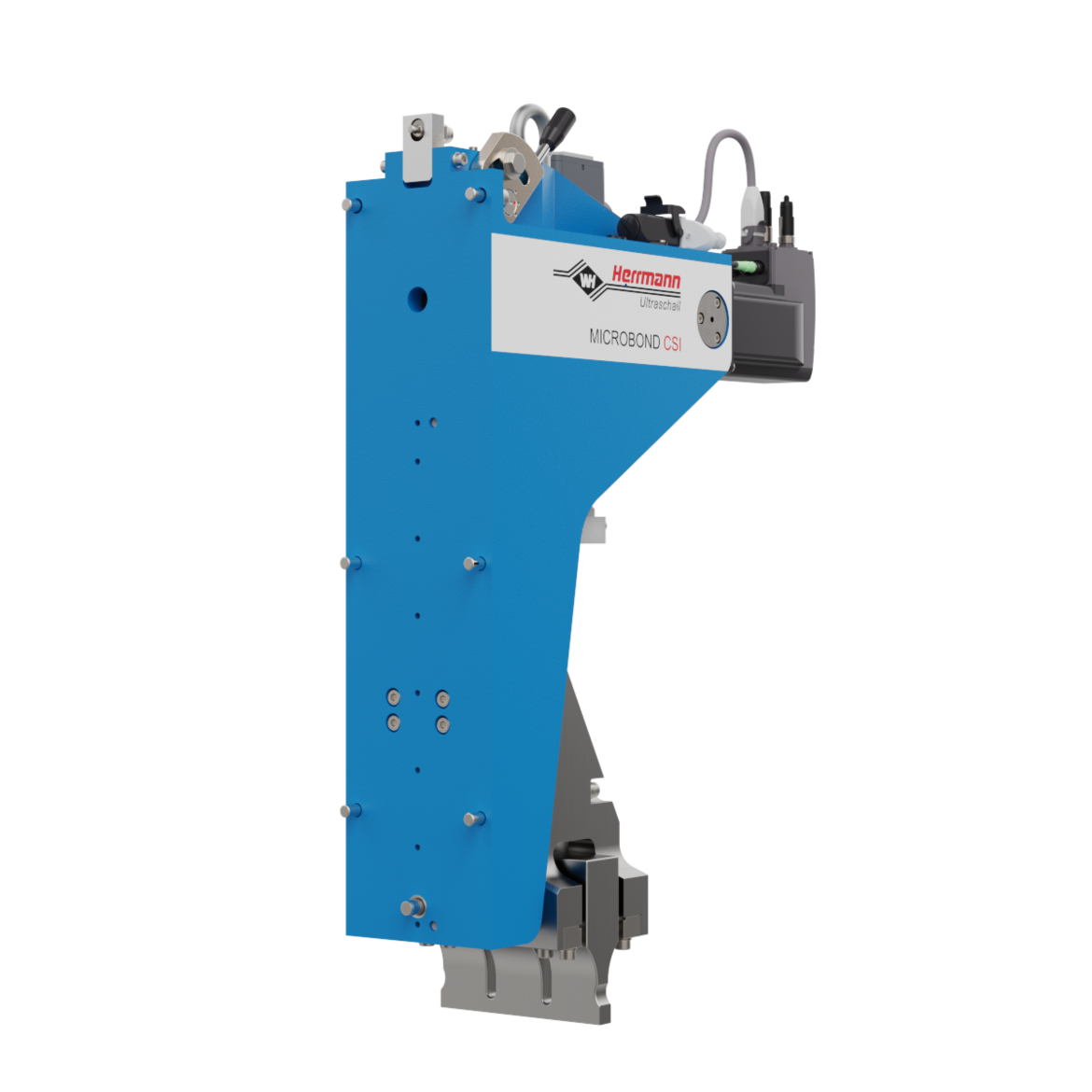

MICROBOND CSI systems

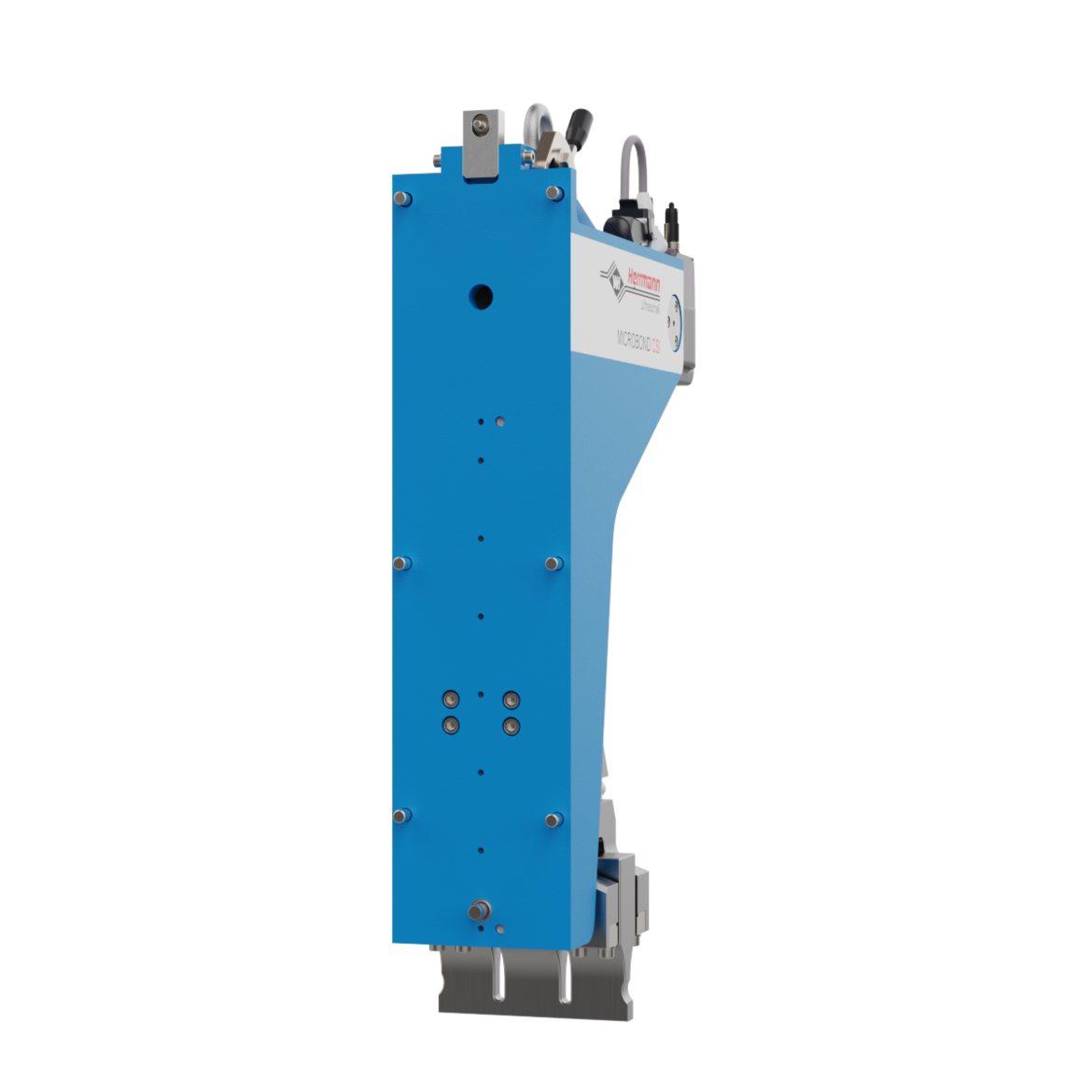

The MICROBOND CSI system, consisting of the actuator, controller and high-performance generator guarantees consistent weld quality. A reliable and at the same time highly precise mechanical system allows a gap stabilization with the patented gap control system Microgap. Control and visualization of this continuous joining process is performed by the MICROBOND controller. Thanks to consistent amplitude and high continuous ultrasonic power output, process speeds of up to 800 m/min can be realized.

- 20, 30 and 35 kHz operating frequency

- 600 – 4,800 W generator power

- 60 – 4,000 N weld force

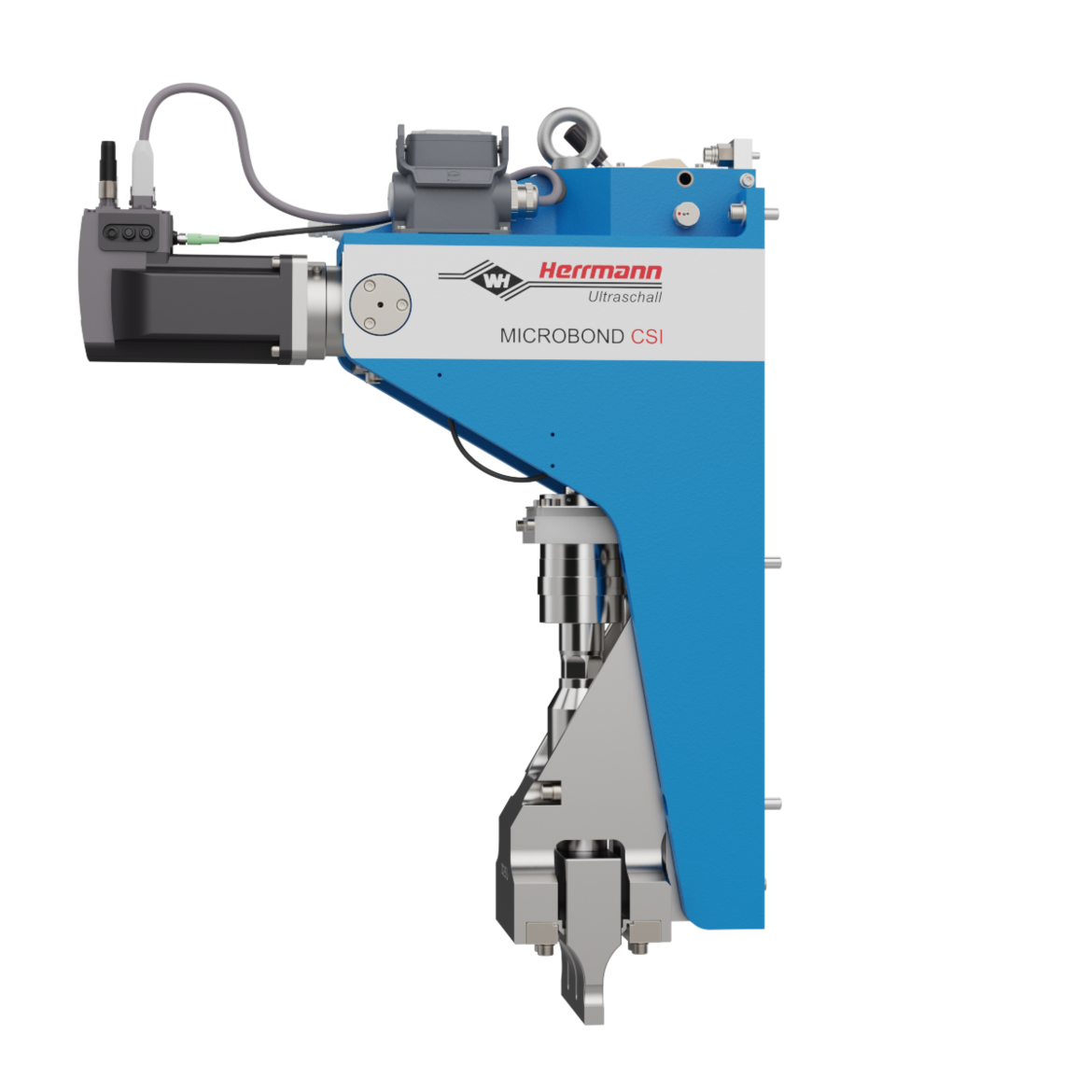

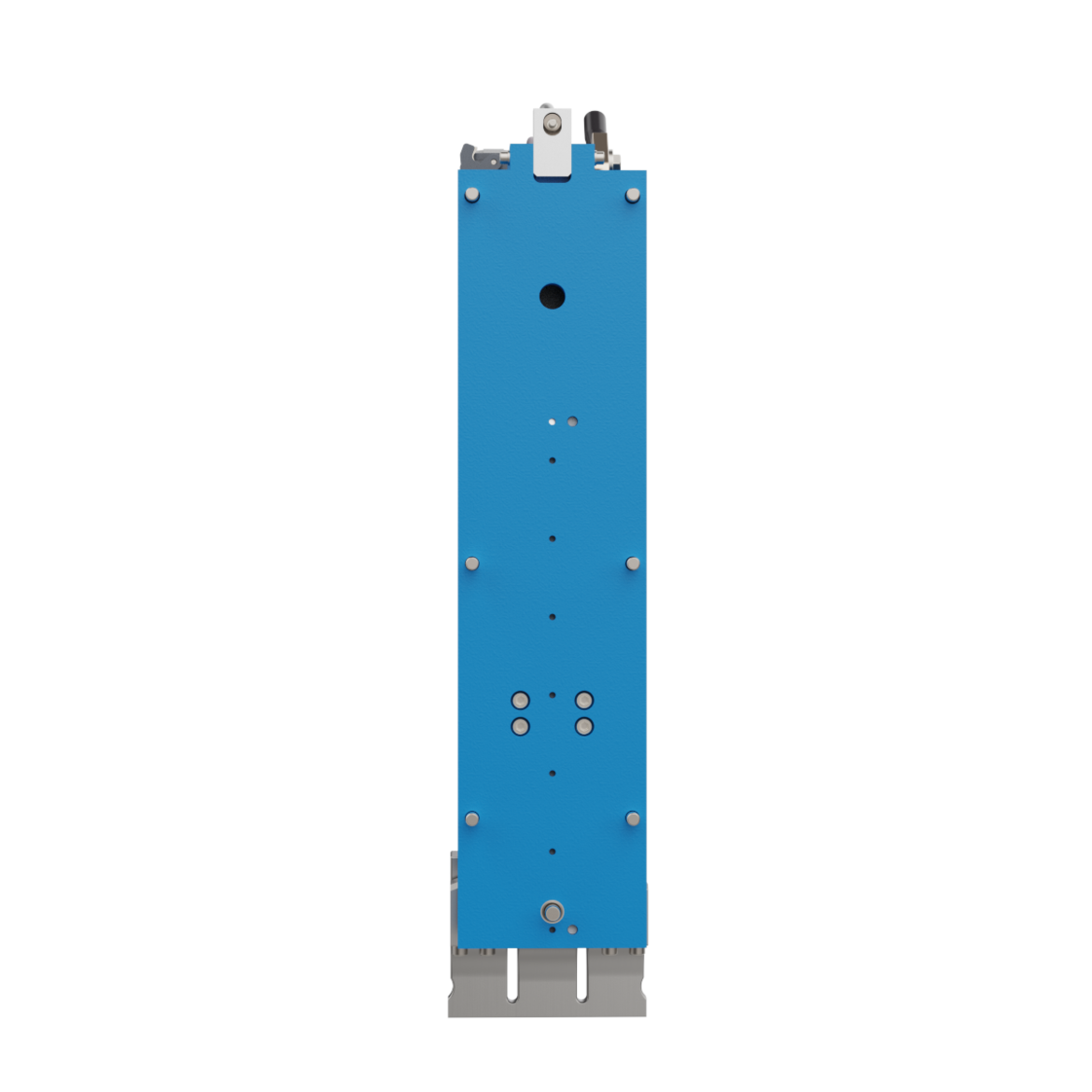

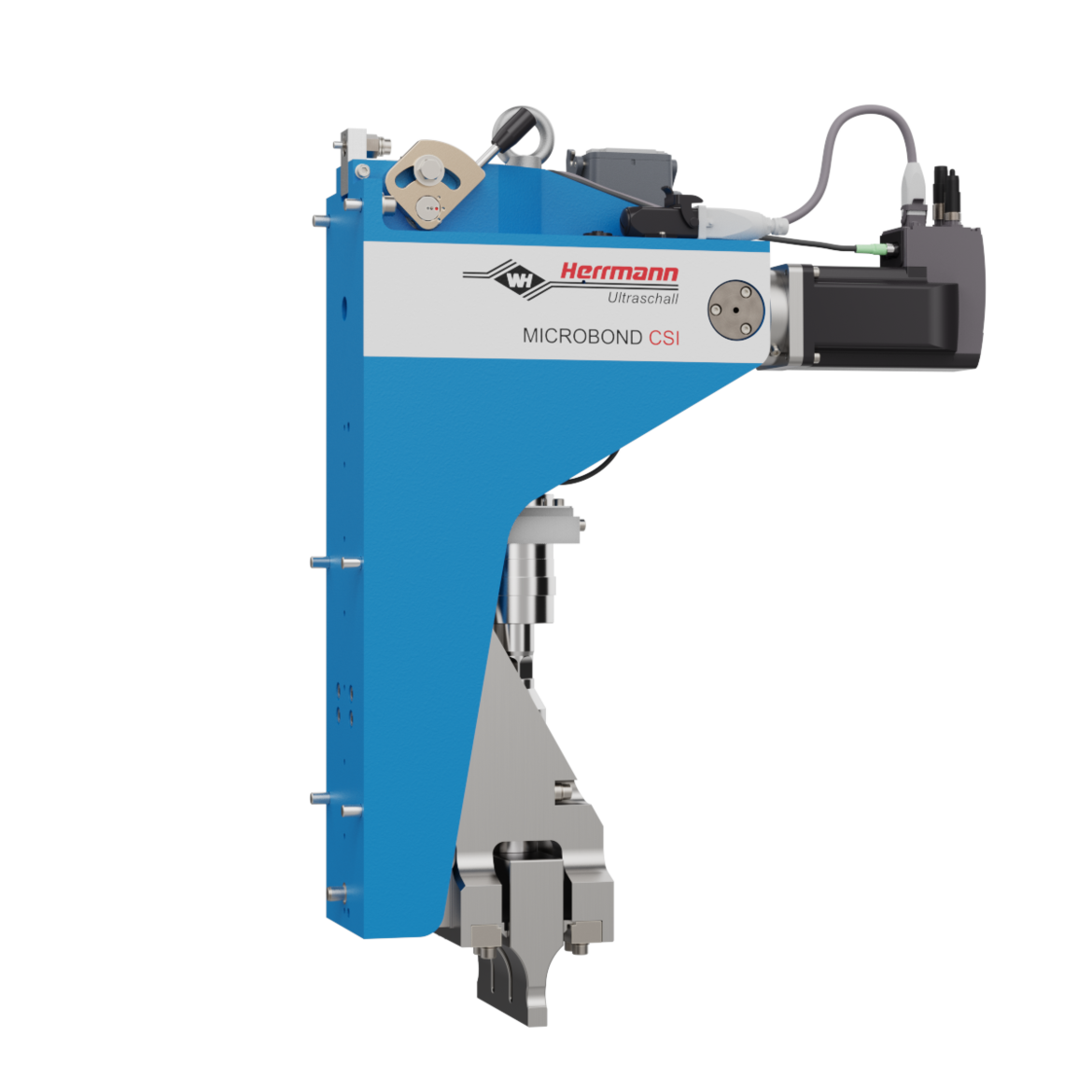

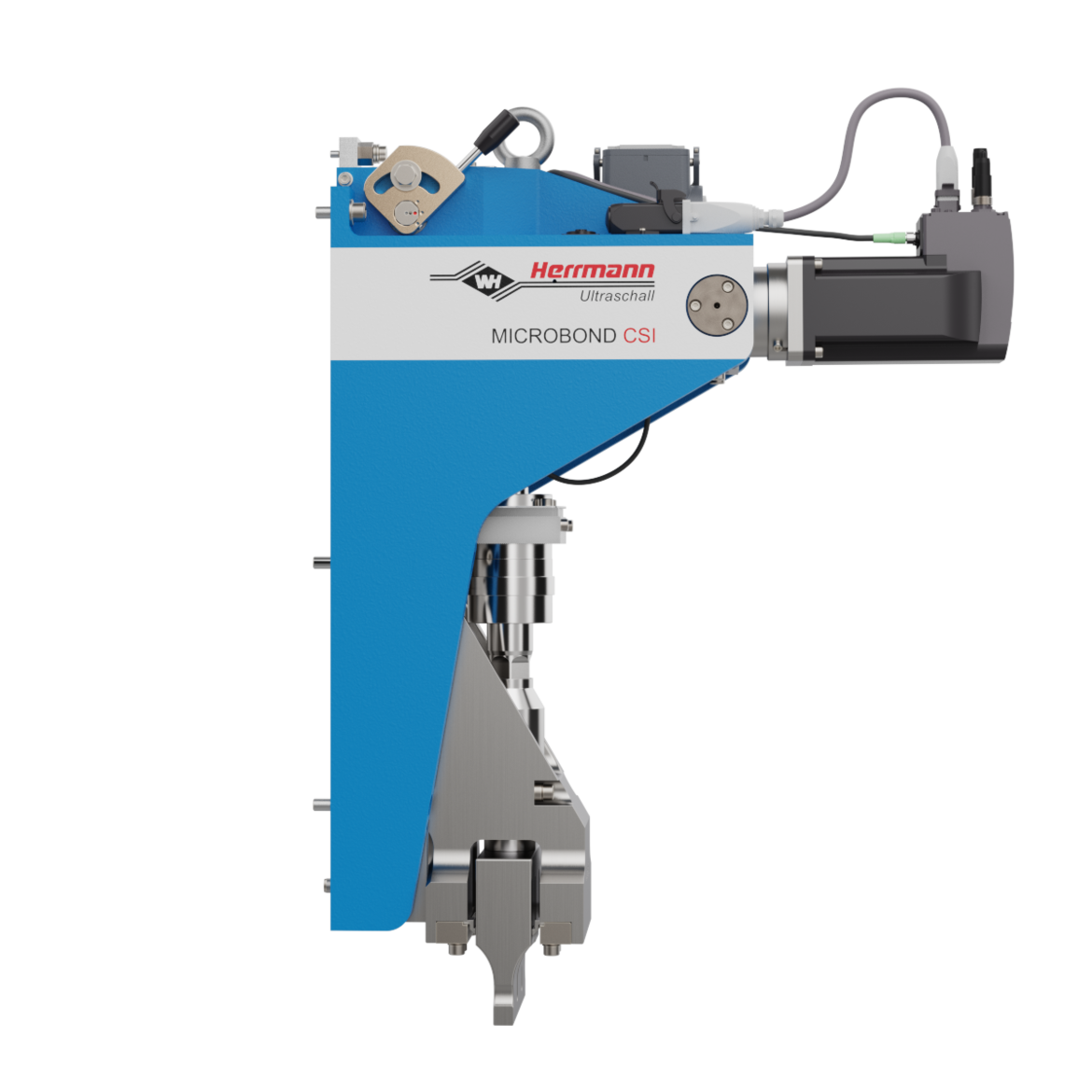

The CSI variants of the MICROBOND product line are characterized by their modular extension options and enable operating widths of several meters. Thanks to the rigid CSI support and the trapezoid sonotrode geometry it is possible to install sonotrodes at minimum distance to one another. The result: a homogeneous end product without disturbing interruptions.

- No sonotrode offset necessary

- Individual control of single weld units

- Expansible production widths

- No distortion of the web material

Herrmann Ultraschall focuses on maximum transparency in the weld process. Only in this way is it possible to understand, control, and monitor the ultrasonic joining process. Prevention of redundant rejects, reduction of standstill time, and high availability guarantee an economical manufacturing process. Thanks to the mobile MICROBOND Control tablet, the process can be monitored, assessed, and optimized directly at the weld station.

- Process visualization of all relevant welding parameters

- Process-oriented user guidance with intuitive operability

- Real time quality control

- System safety for the protection of man and machine

| MICROBOND CSI | 20 kHz |

|---|---|

| Generator power (max. peak power)[W] | up to 4800 |

| Weld force min/max [N] | up to 4000 |

| Control increment [µ] | 0,3 |

| Weight (incl. CSI sonotrode) [kg] | 54 |

| Sonotrode widths* [mm] | 85 / 100 / 161 / 200 / 240 / 270 |

With the MICROBOND Control it is possible to understand, control, and monitor the ultrasonic bonding process. Prevention of redundant rejects, reduction of standstill time, and high availability guarantee an efficient and economical manufacturing process.

- Visual process control

- Real time quality control

- System safety

With simple connectivity, intelligent user interfaces, and full access from the master computer of the production line, the MICROBOND Control ensures straightforward integration into existing and new machine designs. The optional integration modules combine the ultrasonic components with the rotary anvil to form a robust and ergonomic unit.

Process visualization

Graphical display of the time-related curves for all relevant process variables, such as power, position, force, amplitude, and frequency is used for documentation of the continuous course of the weld and therefore enables easy process assessment – the basis for fast and targeted process optimization.

- Visualization of the continuous weld process

- Configurable graph records

Process-oriented user guidance

The process-oriented user guidance provides intuitive navigation through the weld process. Task-oriented menu contents ensure excellent operability from setup to process monitoring.

- Optimum ease of operation and process-oriented navigation

- Consistent menu navigation, available in more than twelve user languages valid worldwide

Real time quality control

For monitoring of the weld process all process variables are continuously displayed and assessed. Establishment of customized process limits enables early detection of incorrect deviations and prevents production of unnecessary rejects.

- Real time process visualization with warning and limit functions

- On-line connection via ethernet I/O for fast process interference and access to all relevant process parameters

System safety

In order to ensure safety of man and machine, the MICROBOND system is equipped with a number of safety features that help rule out potential safety hazards and prevent accidents. Tools and machinery are reliably protected.

Protection from personal damage

- The MICROBOND system with its safety CPU is integrated into the safety circuit of the overall system

- Travel movements of the system in setup mode require enabling via key switch and acknowledge button

Protection from damage of tools

- The metal contact detection unit and the overtravel protection prevent tool contact between the sonotrode and the rotary anvil

- Permanent monitoring of the maximum permissible force and power values protects the MICROBOND module from mechanical overload

Ultrasonic generators

Continuous ultrasonic power generators for continuous applications - The digital ultrasonic generator technology of the ULTRABOND product line is specifically designed for continuous weld processes with continuous power ranges of up to 8000 W. A DSP (Digital Signal Processor) compensates for fault effects and ensures repeatable ultrasonic output at a duty cycle of 100%. The ULTRABOND digital ultrasonic generator is used with the MICROBOND and EASYBOND systems by Herrmann Ultraschall.

More on CSI support

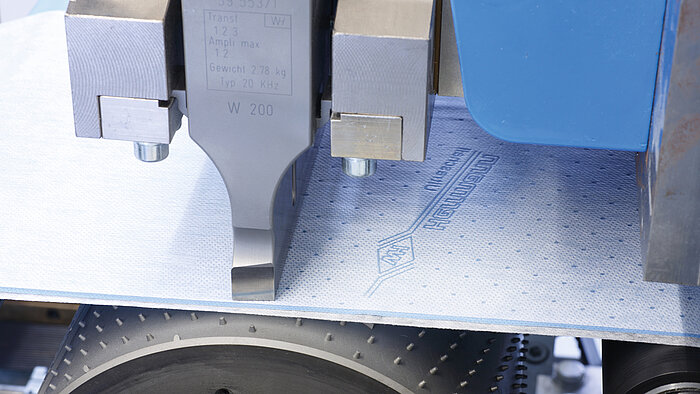

The continuous welding of web material requires the highest level of precision. Even slightest variations in the gap width between the sonotrode and the rotary anvil of a few µm have an influence on good or suspect welds. Mechanical influences such as axial and cross-directional weld forces or temperature-related material expansion must be understood and controlled in detail.

These factors are compensated by the patented CSI support, which ensures that the sonotrode is directly clamped at the vibration node (vibration-free point) by means of a decoupled mechanical system. This reliable support technology maintains consistent weld results, even in applications with large contact pressure areas or intermittent cross-directional weld surfaces.

MICROBOND systems don't just offer a high degree of process safety, they also ensure a long service life during 24/7 production operation. Even in the case of a fault, the intuitive user guidance allows you to find the fault quickly and prevent long recovery times thanks to the corresponding workflows.

VOJISLAV, TECHNICAL ACCOUNT MANAGER

MICROBOND technology – optionally expandable

The CSI variants of the MICROBOND product line are characterized by their modular expansion options. Operating widths of several meters can be realized without any problems. Thanks to the rigid CSI support and the trapezoid sonotrode geometry it is possible to install sonotrodes at minimum distance to one another. The result: a homogeneous end product without disturbing interruptions.

- No sonotrode offset required

- Individual control of single weld units

- Compensation of anvil drum bending

- No distortion of the web material

A fair comparison

Compared to conventional bonding methods, ultrasonic welding using the MICROBOND technology provides an extremely efficient and economical option of bonding materials with each other. For selection of the best suitable joining process, investment costs must not be the sole and decisive factor. A holistic approach includes various viewing angles.

| Holt melt | Thermo bonding | Conventional ultrasonic process (pneum.) | Ultrasonics using MICROBOND | |

| Low energy consumpion | º | º | • | • |

| Less material dependence | • | • | º | º |

| High process availability | º | º | • | • |

| Low integration effort | • | • | • | • |

| High process control | º | º | º | • |

| Ease of maintenance | º | º | • | • |

| Fast ROI | º | º | • | • |

| Low setup time | • | º | • | • |

| Ecological aspect | º | • | • | • |

| High quality control | º | º | º | • |

| Low consumables | º | º | • | • |

º Low degree of performance

• High degree of perfomance