SUSTAINABILITY

Achieve your sustainability goals with our efficient ultrasonic welding technology! With minimal scrap rates and up to 75% less energy consumption, the joining process ensures that your production becomes more environmentally friendly while reducing costs.

Let your Trusted Advisor guide you on how our technology can help you become more sustainable and economical!

- Save resources and energy

- Produce safely, reduce costs

- Perfect for sustainable materials

BJÖRN, Sonotrode Design

“We are the perfect partner to develop your sealing solution for sustainable packaging – whether paper-based, monomaterial, biodegradable or compostable.”

Save resources and energy

- Save up to 75 % energy

- Particularly gentle on materials

- No additional joining agents needed

There is hardly a more efficient technology for connecting materials than ultrasonic welding. Heat is not supplied externally, but is only generated for a short time by friction inside the materials. This means that energy is only consumed where it is actually needed. This protects the materials and saves up to 75 % of energy. In addition, the process does not require any additional joining agents, which further reduces the CO2 footprint and production costs.

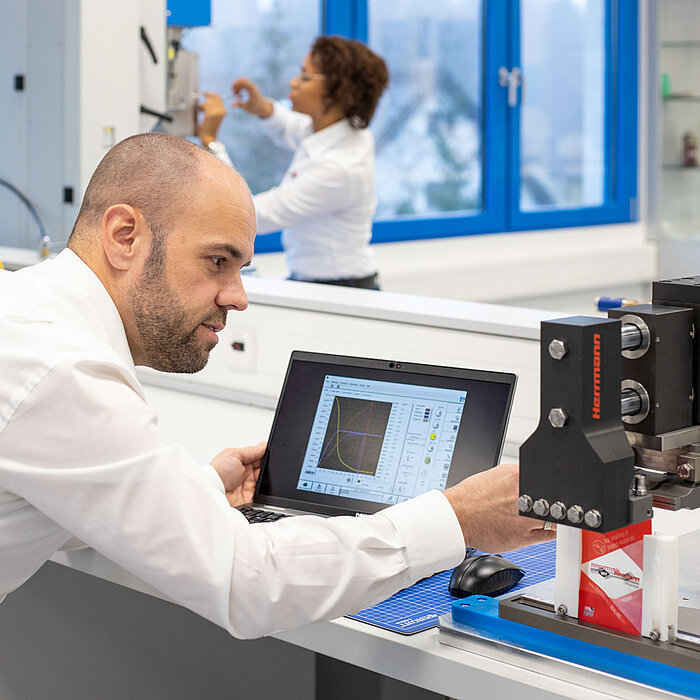

Produce safely, reduce costs

- Precise controller system enables repeatable welding results

- Extensive collection of process data

- Perfect optics even for complex requirements

We help you to minimize your scrap rates. To do this, we determine the perfect welding parameters for your application, so we can guarantee you a repeatable weld result to your exact requirements - even for applications with complex designs. With over 150 parameters measured for each weld, a wealth of data is available to further optimize the process. This enables us to make your production process simultaneously more stable, sustainable and profitable.

Perfect for sustainable materials

- Ideally suited for sensitive materials

- Welding tests with sustainable plastics

- Consulting for material selection

As a particularly gentle joining process, ultrasonic welding is ideal for joining sensitive materials such as paper-based packaging or monomaterials. In addition, we are already researching the development of safe welding processes for bio-based plastics and recyclates. As a result, we can advise on the transition to more environmentally friendly materials and are prepared for tomorrow's requirements.