Ultrasonic technology for masks

Requirements

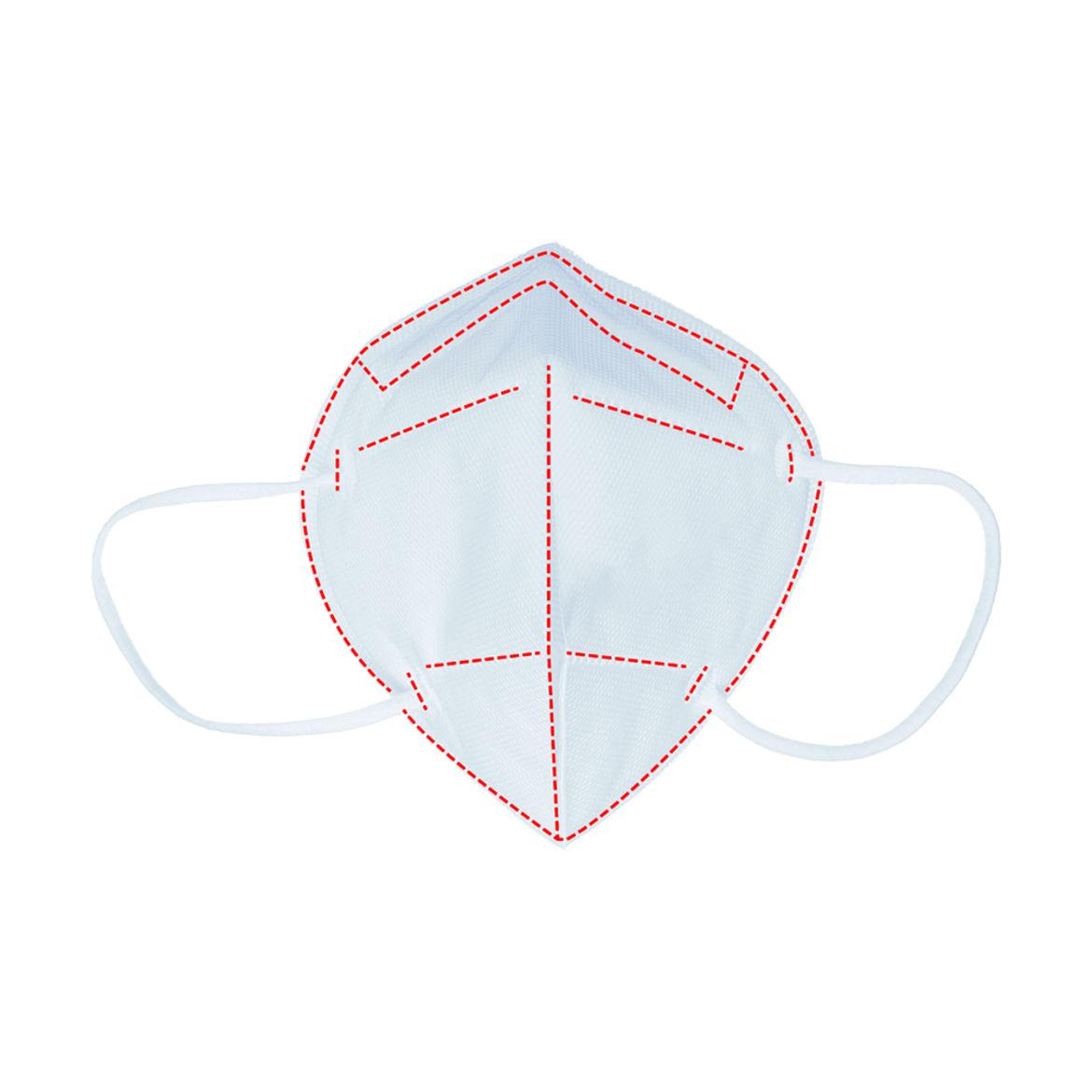

The material structure consisting of several layers is joined at various points by ultrasonic bonding to ensure shape and stability.

Technical solution

For high volumes, the product is being manufactured on a high-speed system with two ultrasonic stations:

- In the first station, the fold and the edging, including the nose clip and the pleat fixation are continuously bonded.

- In the second station, after cutting and turning by 90°, the elastic threads or tapes are intermittently welded.

Configuration options

The MICROBOND CSI system with different sonotrodes and engraved anvils is used in high-speed continuous lines. Welding takes place in two ultrasonic stations. The patented MicrogapControl technology ensures continuous, reproducible bonding quality and allows a production rate of up to 1000 products per minute.

For small quantities, a quick-change system of individual components can be used instead of the MICROBOND CSI system. It is also possible to use a HiQ DIALOG welding machine integrated in a line or as a workstation for intermittent welding

Machine operating principle

-

Web rolls 1,2,3: Three layers of nonwoven material are unwinding (2 protective layers and 1 filter layer); more layers are feasible as well

-

Web roll 4: Nose-clip material (plastics or wire) is cut and fed in between NW material

-

Ultrasonic station 1: Folding, fixing and welding of the longitudinal seams (including inserted nose clip material) as well as welding of the side seams; mask is then cut and rotated by 90°.

-

Web roll 5: Elastic material for ear loops is fed

-

Ultrasonic station 2: Welding of elastic threads or straps onto mask; mask is then stacked and packed

Requirements

The horizontal or vertical fold for the "duck beak" is ultrasonically bonded; the lateral edges and the elastic fixation are also welded. If necessary, a breathing vavle is welded onto the mask by means of ultrasonics.

Technical solution

For high volumes, the product is being manufactured on a high-speed system with three ultrasonic stations:

- In the first station the layers are being bonded together and the nose clip is welded in

- In the second station the elastic bands are affixed

- After folding, the side seams are welded in the third ultrasonic station

Configuration options

The MICROBOND CSI system with different sonotrodes and engraved anvils is used for high-speed continuous lines. Welding takes place in three ultrasonic stations. The patented MicrogapControl technology ensures continuous, reproducible bonding quality and enables a production rate of up to 500 masks per minute.

For small quantities, a quick-change system of individual components can be used instead of the MICROBOND CSI system. It is also possible to use a HiQ DIALOG welding machine integrated in a line or as a workstation for intermittent welding.

Machine operating principle

- Web rolls 1,2,3: Three layers of nonwoven material are unwinding; inlaying melt blown layer determines filtering norm; more layers are feasible as well

- Web roll 4: Nose-clip material (plastic or wire) is unwound, cut and inserted into NW layers

- Ultrasonic station 1: Welding of layers lengthwise (including inserted nose-clip material) and middle fold (duck beak)

- Web roll 5: Elastic material for ear loops is being cut and fed

- Ultrasonic station 2: Welding of elastic threads or straps onto mask; folding of mask for last weld step

- Ultrasonic station 3: Welding of side seams; mask is then stacked and packed

Requirements

With this type of mask, a circumferential weld around the complete edge of the mask is performed, the elastic bands are welded and if necessary, the valve is welded on.

Technical solution

The scope of supply for automated systems consists of a quick-change system with individual components or a VE SLIMLINE.