03. June 2025

, News

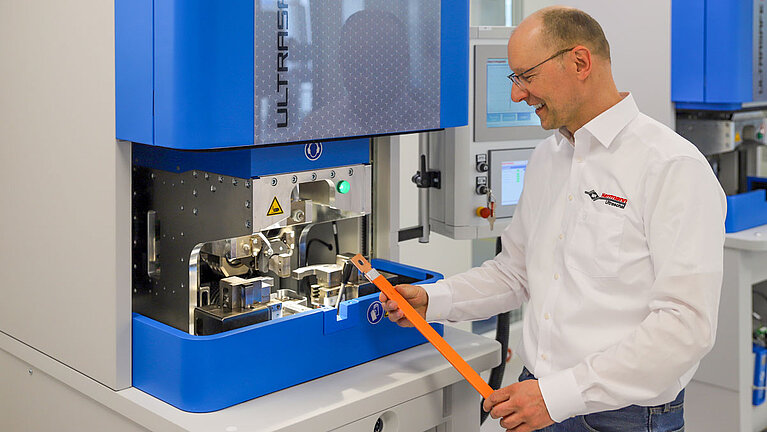

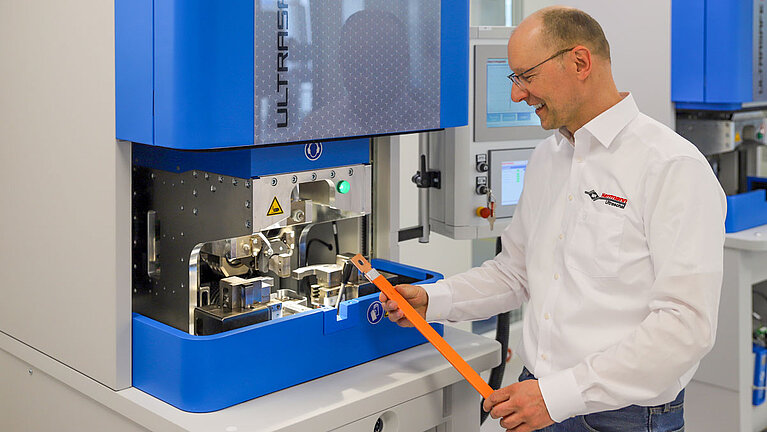

Connecting busbars more efficiently

Efficient joining technologies play a central role in the modern manufacturing of busbars. Especially in the manufacture of busbars, which are used in power distribution systems, electric vehicles and other high-current-carrying applications, choosing the right joining technology is crucial for product quality, production efficiency and cost structure.

Ultrasonic welding has established itself as one of the most economical and efficient technologies for the connection of busbars. Compared to traditional soldering, resistance welding or even laser welding, the process offers a number of advantages that not only reduce production costs, but also minimize manufacturing effort and maximize joint quality at the same time.

Ultrasonic welding utilizes high-frequency mechanical vibrations (usually 20-35 kHz) to create high energy densities in the materials to be joined. These vibrations break up the oxide layers on the surface of the metals and create a material-locking connection through the resulting friction. The advantage of this process is its speed and precision: welding cycles of just a few seconds enable high productivity with low energy consumption costs at the same time.

1. no solder - cost-saving and clean

Traditional joining technologies such as soldering require additional solder, which not only adds to material costs but can also lead to increased vulnerability to defects. For example, the risk of soldered joints being inadequate or coming loose over time is particularly critical for busbars with high current flow and mechanical systems. Ultrasonic welding does not require additional materials such as solder, which not only saves costs but also increases process safety.

2. low scrap - high precision, little material wastage

Another advantage of ultrasonic welding is the low reject rate. As the process is continuously monitored, errors can be identified in real time and the welding process can be adjusted quickly. This means that less material is wasted and manufacturing is more efficient. Busbars are connected with greater precision, which significantly reduces rejects caused by faulty connections.

3. energy efficiency - low operational costs

The energy consumption of ultrasonic welding is significantly lower compared to other processes such as resistance welding or laser welding. As fast welding cycles are performed, the process only requires short energy pulses to make the connections. This leads to lower energy costs, which enables noticeable cost reductions, especially for large production volumes. In addition, the heat is only created directly at the joint, which reduces the load on the welding components and extends their service life.

4. short cycle times - efficient manufacturing

Cycle time plays a decisive role in the manufacturing of busbars. To remain competitive, production processes must be fast and flexible. Ultrasonic welding systems make it possible to carry out welding cycles in just 7-12 seconds. These short cycle times make ultrasonic welding particularly attractive for the mass scale production of busbars, where high quantities need to be manufactured in a short time. Thanks to the short cooling times, companies can achieve high production rates without compromising on joint quality.

5. easy integration into existing systems

Ultrasonic welding systems are space-saving and can be easily integrated into existing or new production lines. The flexible controller technology and modular components allow the system to be easily adjusted to the specific requirements of manufacturing. Experienced ultrasonic partners offer support during integration and start-up, ensuring that the production process runs quickly and smoothly.

Ultrasonic welding is an economically attractive and technologically advanced solution for the connection of busbars. With low operational costs, high precision and fast cycle times, it is the ideal technology to fulfil the requirements of modern manufacturing processes. With the ability to join differences in materials and achieve high strength, ultrasonic welding offers a sustainable and reliable solution for the efficient manufacturing of busbars in a wide range of industrial applications.

Learn more about ultrasonic welding of busbar applications in this whitepaper: